ABOUT US

(1) Quality management situation

Since its establishment in 2002, the company has been engaged in operational management, establishing a sound organizational structure and production management system. The current business premises cover an area of over 1000 square meters and employ more than 50 people. The company implements a regular meeting system to regularly report on the operation of various departments, and promptly improve any problems discovered, in order to continuously improve the modernization and standardization of quality management level of the enterprise, and provide satisfactory products and services for customers and related enterprises.

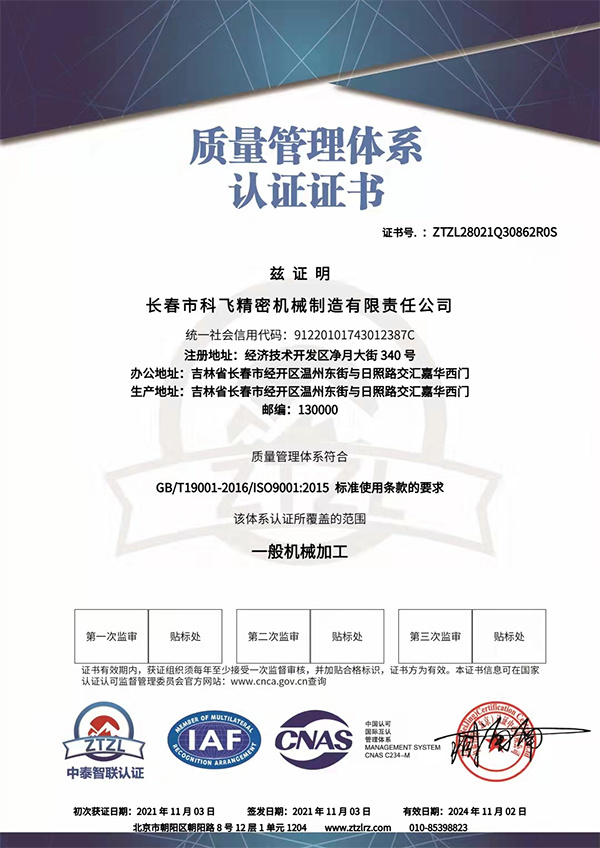

2021

Obtain the GB/T19001-2016/ISO9001:2015 quality system certification, prepare corresponding quality manuals, procedural documents, and work instructions, and implement management according to standards.

2022

Starting to establish and test the GJB9001C-2017 weapon and equipment quality certification management system, establishing a confidentiality management system, establishing and improving confidentiality systems, and building key departments for confidentiality.

2023

Was rated as a national high-tech enterprise, obtained the high-tech enterprise certificate, and was awarded the title of provincial and municipal specialized, refined, and new enterprise.

(2) Quality control situation

Our company has an independent quality inspection department, and quality inspectors are familiar with industry related quality standards and basic knowledge of product quality management and control. They are able to conduct quality testing and analysis on products and provide improvement suggestions. The company has complete measuring tools and inspection tools related to product quality inspection. The verification department of measuring tools and inspection tools is Changchun Institute of Optics, Precision Mechanics and Physics, Chinese Academy of Sciences, and the verification cycle is one year. The product strictly follows the quality management system, and all processed parts are manufactured in accordance with the company's quality control system, with qualified quality inspection reports before leaving the factory.

First article inspection

Batch production requires separate first piece processing, and subsequent batch production can only be carried out after the full sequence and dimensions of the first piece meet the requirements of the drawing.

Process inspection

During the processing, it is necessary to ensure that each process is inspected. Without the qualification mark of the previous inspection, it cannot be transferred to the next processing. Outsourced processed parts or outsourced processes need to be separately inspected and enter the factory after passing the quality inspection.

Full size inspection

During the inspection process, the quality inspector needs to inspect all dimensions marked in the drawings one by one and issue a complete quality inspection report for all dimensions.

(1) Quality management situation

Since its establishment in 2002, the company has been engaged in operational management, establishing a sound organizational structure and production management system. The current business premises cover an area of over 1000 square meters and employ more than 50 people. The company implements a regular meeting system to regularly report on the operation of various departments, and promptly improve any problems discovered, in order to continuously improve the modernization and standardization of quality management level of the enterprise, and provide satisfactory products and services for customers and related enterprises.

2021

Obtain the GB/T19001-2016/ISO9001:2015 quality system certification, prepare corresponding quality manuals, procedural documents, and work instructions, and implement management according to standards.

2022

Starting to establish and test the GJB9001C-2017 weapon and equipment quality certification management system, establishing a confidentiality management system, establishing and improving confidentiality systems, and building key departments for confidentiality.

2023

Was rated as a national high-tech enterprise, obtained the high-tech enterprise certificate, and was awarded the title of provincial and municipal specialized, refined, and new enterprise.

(2) Quality control situation

Our company has an independent quality inspection department, and quality inspectors are familiar with industry related quality standards and basic knowledge of product quality management and control. They are able to conduct quality testing and analysis on products and provide improvement suggestions. The company has complete measuring tools and inspection tools related to product quality inspection. The verification department of measuring tools and inspection tools is Changchun Institute of Optics, Precision Mechanics and Physics, Chinese Academy of Sciences, and the verification cycle is one year. The product strictly follows the quality management system, and all processed parts are manufactured in accordance with the company's quality control system, with qualified quality inspection reports before leaving the factory.

First article inspection

Batch production requires separate first piece processing, and subsequent batch production can only be carried out after the full sequence and dimensions of the first piece meet the requirements of the drawing.

Process inspection

During the processing, it is necessary to ensure that each process is inspected. Without the qualification mark of the previous inspection, it cannot be transferred to the next processing. Outsourced processed parts or outsourced processes need to be separately inspected and enter the factory after passing the quality inspection.

Full size inspection

During the inspection process, the quality inspector needs to inspect all dimensions marked in the drawings one by one and issue a complete quality inspection report for all dimensions.

Phone: 19975811078

Address: 340 Jingyue Street, Economic Development Zone, Changchun City

Record number: Ji ICP No. 2023001013

Phone: 19975811078 Address: No. 340 Jingyue Street, Economic Development Zone, Changchun City Record number: Ji ICP No. 2023001013